Tag Archives: Oilfield vertical cutting dryer

Centrifuge & Dryer in Operation at Drilling Site

After one-month operation, TR decanter centrifuge and vertical cutting dryer get positive feedback from our customer. They both have good and stable performance in oil and gas drilling field. We have rich experience on designing and manufacturing turnkey treating equipment which can be effectively used to treat different kinds of drilling waste includes OBM, WBM and SBM.

TR decanter centrifuge and vertical cutting dryer get positive feedback from our customer.

The model of decanter centrifuge is TRLW450N-2 with handling capacity of 50m3/h. Bowl diameter is 450mm, and bowl length is 1250mm. Rotary speed could arrive 3200rpm. This centrifuge is used to treat the particles ranging from 5μm-7μm. TR Decanter Centrifuge can meet with different requirements of mud treatment under various drilling conditions. In addition, model of our vertical cutting dryer is TRCD930C with handling capacity 30-50T/h. TR Vertical cutting dryer has been done strict balance testing for all major rotary components to minimize vibration & noisy. It is the ideal products for oil based drilling waste management.

Our dryer and centrifuge support oil drilling.

If you are looking for ideal equipment for your drilling waste management? TR Solids Control is your good choice. We have different schemes for both WBM and OBM. TR is a professional supplier of solid control equipment, mud recycling system and various petroleum equipment. Our products have been exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia, African, Australia, Europe etc. Our company is willing to cooperate and make common progress with friends at home and abroad with first-class products, first-class service and reasonable prices.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web:www.trsolidscontrol.com

www.drillingmud-system.com

Decanter Centrifuge & Vertical Cutting Dryer for Drilling Company

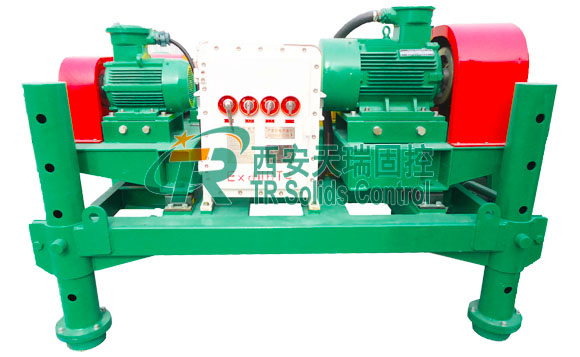

TR Solids Control has rich experience in designing and manufacturing decanter centrifuge and vertical cutting dryer. At this week, we shipped new solid control equipment to our domestic drilling field. It includes 1pc TRLW450N-2 decanter centrifuge and 1pc TRCD930C vertical cutting dryer. The final installation and commissioning work has been completed and is expected to be delivered to our old customer in the short term.

Decanter centrifuge and vertical cutting dryer are ready for delivery.

Decanter centrifuge is the fourth solid control equipment in handling drilling fluid. According to different rotary speed, it can be divided into middle speed centrifuge, high speed centrifuge and high speed frequency centrifuge. Our model TRLW450N-2 belongs to high speed type and has long bowl length 1250mm, bowl diameter is 450mm. Its rotary speed could arrive 3200r/min. TRLW series decanter centrifuge delivers high fluid-recovery rates and efficient solids control to significantly reduce the costs of makeup fluids and disposal.

Vertical cutting dryer and decanter centrifuge will be shipped to drilling company.

Vertical Cutting Dryer is one of the popular products for OBM and WBM. It is a kind of drying machine for handling mud in oilfield. The capacity of our model TRCD930C vertical cutting dryer is 30-50 T/h. Maximum basket diameter is 930mm, and rotary speed is 900 r/min. It has two electric motors, main motor power is 55kw, and oil pump power is 0.55kw. In addition, we have variable-frequency models available to customers’ requirements. TRCD series vertical cutting dryer can recover the oil cuttings in the composition, oil content of cuttings after treatment is generally less than 3%.

TR exported directly or sold with supporting drillers to more than 30 countries and regions in the world such as Russia, United States, Australia, Latin America and the Middle East etc. Making sure to support first-class solid control equipment with developing “Made in China” as our own tasks. Holding forward-looking to each task, every drawing has technicity to direct, every process has worker to follow up and every product has QC to check on. To provide customers with a full set of solid control equipment solutions effectively is our company’s goal.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web:www.trsolidscontrol.com

www.drillingmud-system.com