Drilling Waste Managemnet System

Oil Drilling Solid Control can be refered as DWM (Drilling Waste Managemnet System),it ia a highly vital part of oil&gas drilling.Solids control is a technique used for well drilling to provide prepared drilling fluids for drilling rigs. Drilling fluid maintenance cost, clean up, and disposal cost as well as the overall cost of boring can be reduced dramatically when proper solids control techniques are utilized.

TR Drilling Waste Managemnet System is used for taking drilling fluids from the drilling cuttings and clean the fluids for resuse.It is to maximize the recycling of drilling fluids,and minimize the drilling waste in order to save cost for operators.There are two ways to recovery drilling cuttings,but their purpose is the same.

Drilling Waste Managemnet System Parameter

| S/N | S/N | Description |

| 1 | Vertical Cuttings Dryer | TRCD930 with option for VFD or fixed speed |

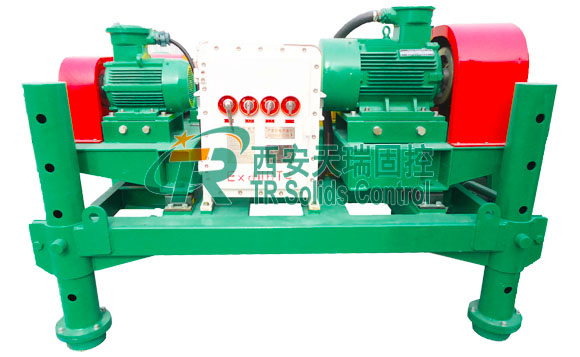

| 2 | Decanter Centrifuge | TRGLW355Centrifuge 14inch bowl,Optional model as below: TRGLW355 Centrifuge with VFD drive. TRGLW355 standard with fixed speed |

| 3 | Screw Pump | Two sets TRG30A-075 Screw Pump with capacity:30m³/h for each pump. One for taking fluids from catching tank to feed the decanter centrifuge,the other for flushing the Vertical dryer. |

| 4 | Skid with catching tank | Fast move skid for mounting all the equipment One Catching tank with capacity:4m³ for catching fluid from vertical cuttings dryer. |

| 5 | Telescopic Skid | Two telescopic skid with walkways and handrails for safe operation. One for mounting the decanter centrifuge to a higher position in order to allow the centrifuge discharged fluids feed to active mud system by gravity. The other telescopic skid for mounting and adjusting the height of the vertical cutting dryer to allow the discharge of drying cuttings |

| 6 | Electric Cradle | 0.5 Tons electric cradle for lifting the components of vertical dryer |

| 7 | Electric Control System | Two lighting system,electrical control boxes and cables and plugs for operation the complete syste |

Advantage of Drilling Waste Management System:

- For oil based drilling cuttings, normally it can reduce the oil on the cuttings to 3% to 5%.

- For water based drilling cuttings, normally it can reduce the moisture content for easy transportation.

- Recycling drilling fluids for reuse to save cost .

Drilling waste management system mainly including cutting dryer( vertical centrifuge), horizontal decanter centrifuge, transfer pump,etc

1. Screw conveyor or vacuum transfer pump to feed material to vertical cutting dryer.

2.Vertical cutting dryer handle the oil based mud to less than 5% OOC(oil on cuttings),cuttings are discharged, oil are recycled.

3. Decanter centrifuge recover the useful drilling fluids from the mud.

4.TR Solid Control is the professional API&ISO certified solids control and drilling waste management system including complete equipments manufacturer in China.

Welcome customers from all over the world to visit us and cooperate with us!

TR Solids Control

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019379

Call:+86-13186019379

E-mail:sales@trsolidscontrol.com

E-mail:sales@trsolidscontrol.com