Tag Archives: Drilling waste management

OBM Drilling Waste Management Shipment

As the professional manufacturer in China, TR Solid Control could design and manufacture various model Drilling Waste Management or or Cutting Dryer System according to the customers requirement. On May.10th, one new batch of oil based drilling waste management was shipped to our old customer. Currently this system is widely used in Chinese domestic market for compact structure and high efficiency.

Oil based drilling waste management was shipped to our old customer.

This system is composed of TRCD930C vertical cutting dryer, TRLW355N-1 high speed centrifuge, mud tank, centrifuge supply pump and other auxiliary accessories. Processing capacity of our dryer could reach up to 30-50 T/h with basket diameter 930mm. Rotary speed is 900r/min. Bowl diameter of our TRLW355N-1 centrifuge is 350mm, and bowl length is 1250mm. Processing capacity is 40m3/h. TR drilling waste management system can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings and stabilizes the liquid phase performance.

Our drilling waste management is with compact structure and high efficiency.

TR Solids Control is one of the most famous international brand for Mud Solids Control System & Drilling Waste Management in China. We have one stop service for Solids Control Solution of your oil gas drilling, CBM drilling, HDD, and water well drilling as well as the construction drilling mud treatment etc. For more information about our drilling waste management, please visit: www.trsolidscontrol.com/drilling-management-system.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com

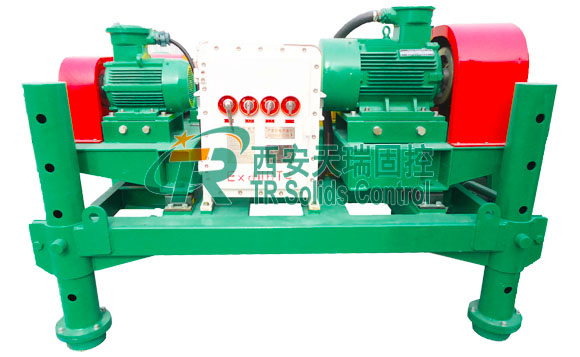

Centrifuge & Dryer in Operation at Drilling Site

After one-month operation, TR decanter centrifuge and vertical cutting dryer get positive feedback from our customer. They both have good and stable performance in oil and gas drilling field. We have rich experience on designing and manufacturing turnkey treating equipment which can be effectively used to treat different kinds of drilling waste includes OBM, WBM and SBM.

TR decanter centrifuge and vertical cutting dryer get positive feedback from our customer.

The model of decanter centrifuge is TRLW450N-2 with handling capacity of 50m3/h. Bowl diameter is 450mm, and bowl length is 1250mm. Rotary speed could arrive 3200rpm. This centrifuge is used to treat the particles ranging from 5μm-7μm. TR Decanter Centrifuge can meet with different requirements of mud treatment under various drilling conditions. In addition, model of our vertical cutting dryer is TRCD930C with handling capacity 30-50T/h. TR Vertical cutting dryer has been done strict balance testing for all major rotary components to minimize vibration & noisy. It is the ideal products for oil based drilling waste management.

Our dryer and centrifuge support oil drilling.

If you are looking for ideal equipment for your drilling waste management? TR Solids Control is your good choice. We have different schemes for both WBM and OBM. TR is a professional supplier of solid control equipment, mud recycling system and various petroleum equipment. Our products have been exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia, African, Australia, Europe etc. Our company is willing to cooperate and make common progress with friends at home and abroad with first-class products, first-class service and reasonable prices.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web:www.trsolidscontrol.com

www.drillingmud-system.com

Shale Shaker & Mud agitator for Drilling Waste Management

Recently, 2pcs TRZS703 high-frequency shale shakers and 8pcs TRJBQ11 mud agitators were finished the final inspection and package in TR workshop. They are on the way to water-based drilling waste management site. TRZS703 shaker is one of linear motion shale shakers in our company. Its processing capacity is 130m³/h, and supporting motors are two 2.2kw explosion-proof motors. Screen specifications are 700mm×1250mm×3 pcs. The screen area is 2.6㎡, and adjustment angle of the shaker box is: -3°~+3°. We can adjust the angle of shaker box to control the degree of dryness and wetness of mud at the outlet. Motor power of our TRJBQ11 mud agitator is 11kw with explosion-proof motors.

Shale shakers and mud agitators are completed the final package.

TR Solids Control is a professional manufacturer of solid-liquid separation plant in China for more than 10 years. Our company has been devoted to the research of solid-liquid separation for a long time and has achieved great results in this area. The shale shakers and mud agitators ordered by our customer are all drilling waste management modules used in shale gas drilling and production. Larger particles in the waste slurry are separated by shale shakers, thereby reducing the pressure of filter press part and also protecting the filter cloth. Mud agitator is used in mud storage tank and feeding tank to prevent the mud from settling in the tank.

Linear shale shakers and mud agitators are shipped to drilling waste management.

The solid-liquid separation equipment manufactured by TR Solids Control can be applied to oil & gas mining, drilling waste management, horizontal directional drilling, subway shielding, city piling, and other different drilling construction sites. If you have any requirement recently, welcome to contact TR sales team at any time. We can customize suitable solid-liquid separation unit or system according to your construction requirements.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web:www.trsolidscontrol.com

www.drillingmud-system.com

Oil-Based Drilling Waste Management

In order to implement and follow environment requirements, TR Solids Control developed a set of drilling waste management independently. This system makes the mud pit disappear completely, and can realize harmless treatment during drilling. TR team has made our own contribution to environmental protection.

Oil-based drilling waste management, liquids solids separation, DWM manufacturer

Our oil-based drilling waste management is mainly divided into waste drying collection unit, liquid phase separation unit. As for disposal of waste mud, we need to add gel breaker processing unit.

1.Thermal Washing Facility

In this process, thermal washing facility will be injected into a certain percentage of hot water. Then we transport oil-base mud drilling cuttings to the thermal washing facility with screw conveyor. The oil from the drilling cuttings off in the stirring of mixer continuously. At this time, the thermal washing facility completes this process.

2. Waste Drying Collection Unit

In this process, we transport the drilling cuttings treated by solids control equipment to high-frequency vertical cutting dryer with screw conveyor. After dryer treating, large particles of drilling cuttings in solids control equipment are separated and stripped.

(Solid-phase water content can be controlled within 10%) Drilling waste cuttings are collected and transported timely to the lower tank for caching and pre-treatment.

3. Liquid Phase Separation Unit

In this process, we transport the mud filtered by vertical cutting dryer to variable-frequency high speed centrifuge through industrial pump(screw pump) of the centrifuge for deep separation. After treatment, solid phase separated is collected, and liquid phase will be transported to drilling fluids circulating system for recovery through sand pump.

Mud circulating system, oil sludge treatment system, solids control unit

As a main and well-known manufacturer of solids control equipment and drilling waste management, TR Solids Control always put customers’ requirement in the first place. If you have any inquiry about shale shaker, shaker screen, mud cleaner, desilter, desander, mud agitator, jet mud mixer, decanter centrifuge, centrifugal pump, shear pump etc, welcome to contact us freely. TR will provide our best price and service to you.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Process of HDD Mud Recovery Purification System

Horizontal directional drilling short name is HDD. This technology has wide application in oil and gas pipelines crossing the rivers, lakes, highway, railway hub and other obstacles and important area. HDD site is all in large no-excavation area and do not allow to make mud discharge randomly, so it is very important to equip with mud recovery system. TR Solids Control is a professional manufacture in designing and customizing HDD mud recovery purification system.

500GPM HDD mud system, drilling waste management, mud cleaning system

The process of HDD mud recovery purification system:

The whole system consists of a mud recovery treatment unit and a mud preparation unit.

- Before construction, using mud mixing device to blend fresh water with mud material, achieving the purpose of mud preparation;

- Using mud pump to supply the prepared slurry to the wellhead;

- Return of waste mud from the wellhead is pumped to the shale shaker in the mud treatment unit, and the waste mud is removed through the mud shale shaker to remove a large amount of the waste solid particles. The treated slurry liquid will continue to be supplied to mud cleaner through sand pump, after treatment the liquid can meet using requirements. Because after this system treated, solid particles content in slurry liquid is 75 microns.

HDD mud system, slurry treatment system, drilling fluids treatment system

The Function of HDD mud recovery purification system:

- You can recycle the used mud, and reduce construction costs;

- Reduce the preparation work of mud, also reduce labor cost.

- Reduce environmental pollution, and be friendly.

HDD trenchless drilling site, mud recovery system for HDD No-dig project

TR Solids Control is a top manufacturer of Horizontal Directional Drilling(HDD) Mud Recovery Purification System. Our mud system has been exported to many countries for HDD and CBM drilling operation, especially popular in Romania, UAE, Nigeria, Indonesia, India, Argentina etc. TR Shale shaker, mud cleaner, desilter & desander, mud agitator, mud gun, jet mud mixer, centrifugal pump, screw pump, submersible slurry pump, shear pump are with good price and top quality. We will provide one-stop service to you!

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-15229092385

Call:+86-15229092385

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com