Presentation of YZ Series Submersible Slurry Pump

Our YZ series submersible slurry pump mainly supply mud for shale shaker and decanter centrifuge from the mud pit. Its structure is single sucking cantilever type, it uses bearing seat, supporting seat and pipe to connect the hydraulic parts of pump, and liquid is discharged from the hydraulic hose assembly. Pump’s impeller is semi-open type, and it’s equipped with mixing bladed in the stretch part of impeller inlet. The main features of submersible slurry pump are have enough rigidity in submerged parts of the shaft, and don’t set bearing and shaft seals between the impeller and pump, and could convey the medium containing solid particles with larger density. The standard length of pump inserting liquid is 1.3 meter, and can be equipped with a suction tube if required. We operate shaft seals by inserting the pump into liquid. The transmission works by vertical motor mounted on the bearing base, connected by coupling and the pump.

Submersible slurry pump for HDD, Drilling submersible slurry pump, China submersible slurry pump

Technical parameters of YZ series submersible slurry pump:

| Model | Flow | Lift | Speed | Motor |

| 50YZ25-12 | 25m3/h | 12m | 1430r/min | 3kw |

| 50YZ20-18 | 20m3/h | 18m | 1430r/min | 4kw |

| 80YZ50-20B | 40m3/h | 16m | 1440r/min | 5.5kw |

| 80YZ50-20 | 60m3/h | 17.5m | 1440r/min | 7.5kw |

| 80YZ80-20 | 90m3/h | 22m | 1460r/min | 11kw |

| 100YZ100-30A | 75m3/h | 30m | 1470r/min | 18.5kw |

| 100YZ100-30 | 60m3/h | 36m | 1470r/min | 22kw |

| 100YZ160-38B | 82m3/h | 33m | 1480r/min | 30kw |

| 100YZ120-60 | 120m3/h | 40m | 1480r/min | 45kw |

| 150YZ250-40A | 135m3/h | 35m | 1480r/min | 55kw |

| 150YZ250-40B | 120m3/h | 28m | 1480r/min | 37kw |

Submersible slurry pump for oilfield, good performance submersible slurry pump, submersible slurry pump manufacturer

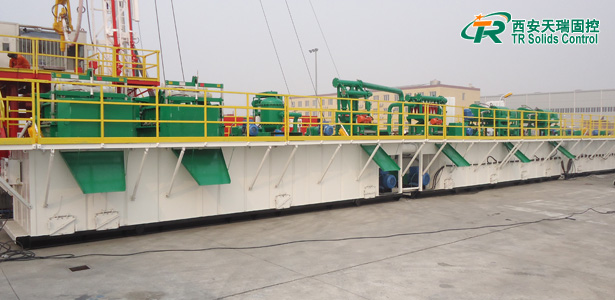

TR Solids Control is a R & D, manufacturing, sales, technical services company in advanced solid control equipment. Besides submersible slurry pump, we also supply top-quality decanter centrifuge, vacuum degasser, shear pump, centrifugal pump, mud cleaner, shale shaker, jet mud mixer, vertical cutting dryer and oil & natural gas slurry purification system, HDD trenchless mud recycling system, piling and shield mud system, river dredging purification system etc.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-15229092385

Call:+86-15229092385

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

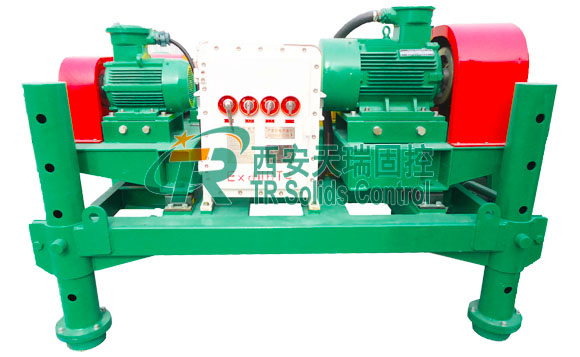

Working Principle of Mud Mixing Hopper

Mud mixing hopper is an important spare part in drilling fluid solids control system, and it’s the most common liquid distribution device. The main purpose of mud hopper is to quickly and uniformly mix the drilling fluid with its additives. In the event of a blowout emergency, by using the hopper large amount of heavier material can be mixed evenly in the shortest possible time. It mainly consists of inlet adjustable connector, tee, nozzles, mixing chambers, venturi pipes, feed hoppers and butterfly valves.

Mud hopper, mixing hopper, jet mud mixer hopper, drilling fluid hopper

Working principle of mud mixing hopper:

The fluid flows into the nozzle with high speed from the inlet adjustable connector, and it quickly jets into tee. At the same time, accretion materials enter tee from the hopper. They mix well, then flow into drill fluid system from venturi pipe. When using mud hopper, the accretions(barite, bentonite, chemistry accretion of mud etc.) of drill fluid is amalgamated homogeneously before it flows into drilling fluid system. It improves fluids properties, exploits the accretions thoroughly, reduces accretions needed, and brings down the mud cost price.

Mud mixing hopper, top quality hopper, TR mud hopper, China mud hopper

TR Solids control is a professional manufacture for mud hopper, jet mud mixer, shear pump, centrifugal pump, screw pump, shale shaker, decanter centrifuge, mud agitator, mud gun etc. Also, mud recycling system are promoted to domestic and aboard. Because we have experienced R&D team, we can help you to customize mud solids control equipment or mud recycling system as your request.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-15229092385

Call:+86-15229092385

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com