Tag Archives: Solids Control System Supplier

How is the TR Mud Recovery System

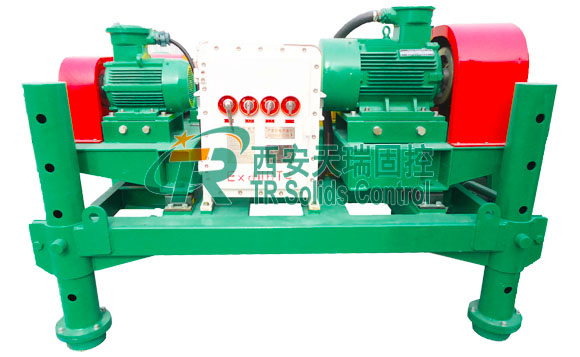

TR Solids Control is a professional manufacturer of solids control system and mud recovery system in China. TR mud recovery system is mainly applied in scenarios such as oil drilling, trenchless engineering, and infrastructure construction. Tr mud recovery system advantages of “integrated design + international certification + high cost performance”. It belongs to the domestic mid-to-high-end tier products. It has passed multiple domestic and international certifications such as API, ISO9001, and ISO14001. It exports cover many countries in the Middle East, Southeast Asia, etc. It has both domestic adaptability and international compliance.

Key parameters and advantages of TR Mud Recovery System

- Large processing capacity: 80m³/h-350m³/h

- High separation accuracy: Solid-phase control accuracy: ≥5μm

- Core technologies: Solidsworks 3D modeling, modular design. The four-stage purification technology (vibrating screen + sand/mud remover + centrifuge) has a higher separation efficiency. Special materials are resistant to abrasion, and the service life of vulnerable parts is over 30% longer.

- After-sales service: Response time: On-site service within 24-48 hours (domestic)

- Personalized customization: It can be specially customized according to the special requirements of customers. Each product is 3D modeled by Solidsworks, allowing customers to have a clearer understanding of the solution.

- Comprehensive certification qualifications: TR Solids Control has passed the American API certification and quality management system certification. Some of the products have passed the CE and CU-TR certifications. And it has multiple products that have passed the CE audit. It has multiple product patents (shale shaker, Drilling Waste Managemnet System)

Disadvantages of TR Mud Recovery System

Although it may not be well-known, the TR mud recovery system works well and is more cost-effective.

The Drilling Solids Control System reduces the rate of drilling accidents

Accidents such as stuck pipe, well leakage and gas invasion not only lead to delays in the construction period. These accidents are directly related to the deterioration of drilling fluid performance and the accumulation of solid impurities. The Drilling Solids Control system through the efficient purification of drilling fluid, has become key device for reducing drilling accidents.

Drilling accidents and Drilling Solids Control system

The root cause of most serious accidents is closely related to the state of the drilling fluid. The core function of the fixed Drilling Solids Control system is precisely to solve these key problems:

| Common drilling accidents | The role of the solid control system |

| Stuck drill | Remove solid impurities and maintain the low solid phase of the drilling fluid. Good liquidity. Avoid rock debris deposition and overly thick filter cakes |

| Well leakage | Purify the drilling fluid and stabilize its rheological properties. Control the filtration loss in combination with chemical treatment agents. Ensure pressure balance |

| Gas intrusion/blowout risk | The vacuum degasser can quickly degas. The purification system maintains the stability of the drilling fluid density. Avoid losing control of stress |

| Drill bit wear | Remove hard sand grains. Maintain the cleanliness of the drilling fluid. Reduce the risk of wear and corrosion |

The drilling solids control system is purified through the process of “shale shaker → desander → desilter → centrifuge”. Achieve precise removal of solid particles of different sizes

The shale shaker removes large rock cuttings of ≥74μm to prevent their deposition in the wellbore. Prevent sand settling and stuck drill from the source.

The desander and desilter separate sand particles of 20-74μm and fine mud of 10-20μm. Reduce the abnormal increase in the viscosity of drilling fluid. Avoid sticking stuck drills and overly thick filter cakes;

The centrifuge can deeply remove ultrafine particles of 5-10μm. Prevent the “deterioration” of drilling fluid, which may lead to an increase in fluid loss.

Drilling engineering with a complete drilling solid control system. It can keep the solid content of drilling fluid below 5%. The occurrence rate of sand settling stuck pipe accidents has been reduced by more than 80%.