Tag Archives: Solid control system

The Components of Solids Control System

Describe the Components of the solids control system

The solids control system is composed of multi-stage purification equipment, auxiliary equipment and pipeline systems. All levels of solids control equipment work in collaboration to achieve purification from coarse to fine.

The Components of Solids Control System

- Mud Shale Shaker:

Primary Solids Control equipment is also the “first line of defense” of the solids control system. The large particle cuttings (with a particle size of ≥74μm) in the drilling fluid are separated by high-frequency vibration.

The processing volume is usually 1.2 to 1.5 times the circulation volume of the drilling fluid, ensuring the efficient operation of subsequent equipment.

mus shale shakers can be classified into linear shale shakers and elliptical shale shakers. elliptical shale shakers are widely used in deep Wells and horizontal well drilling. it features high screening efficiency and strong processing capacity. - Desander:

Secondary Solids Control equipment. The desander adopts the principle of hydrocyclone to separate sand particles with a diameter of 20-74μm from the drilling fluid. It is usually used in conjunction with shale shakers. The sand grains separated by the cyclone fall into the small vibrating screen below to further recover the drilling fluid. - Desilter:

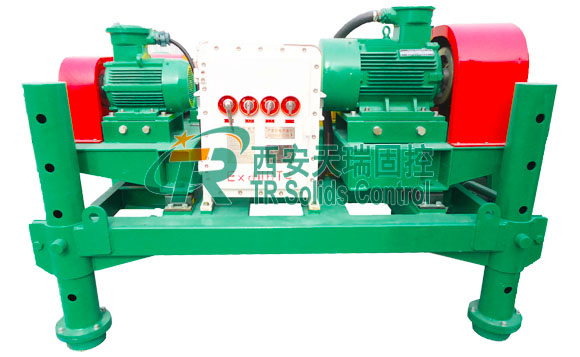

The third level in the solids control system. The sludge separator separates fine sludge particles of 10-20μm. The shaker screens of the deslimer is generally configured with 120 mesh. The sand removal cyclone has a smaller diameter and higher separation accuracy. It can effectively reduce the mud content of drilling fluid and maintain the stability of rheological properties. - Decanter Centrifuge:

Four-level deep Solids Control equipment. Solid-liquid separation is achieved by utilizing centrifugal force. Centrifuges are mainly used to separate ultrafine particles of 5-10μm. It is suitable for precision drilling scenarios with extremely high requirements for drilling fluid performance. It is mainly used for shale gas development and deep-sea drilling. It can enhance the reuse rate of drilling fluid.The centrifuge is components of solids control system.

Other equipment in the Components of Solids Control System:

The Components of Solids Control SystemIncluding drilling fluid tank, agitator, sand pump and vacuum degasser. Together, they form complete solids control system.

ZJ30 Drilling Fluid Mud Circulating System in Production

Drilling fluid mud circulating system is suitable for water-based and oil-based drilling fluid mud circulating processing operations in petroleum drilling. It can realize the functions of drilling fluid preparation, weighting, screening, circulating, control and storage. Our factory has been very busy at this year. We received an order of ZJ30 mud circulating system from old customer at the early of April. Now it’s in intense production in our workshop.

ZJ30 mud circulating system is in production at our factory.

This ZJ30 drilling fluid mud circulating system is composed of mud tank, shale shaker, mud cleaner, jet mud mixer and shear pump etc. All equipment is designed with corrosion and wear resistance, with a long service life. It adopts a centralized electric control, being convenient for operation. With modular design and small footprint, it can be flexibly configured and installed according to the customer’s requirements. This system is commonly used in oil and gas drilling field. In addition, we could supply large capacity mud circulating system for ZJ40, ZJ50 and ZJ70 drilling rig or workover rig.

ZJ30 mud circulating system is used in oil and gas.

TR Solids Control can supply and design complete mud circulating or recycling system for oil and gas drilling projects all over the world. With complete five phrase purification equipment like shale shaker, vacuum degasser, desander, desilter, decanter centrifuge, our mud system ensures good and efficient treatment effects of removing solids particles and gas bubbles in oil and gas drilling fluids. We design and make detailed technical drawing of the system customized according to clients’ special requirements and drilling site application. If you get any requirement, welcome to consult with TR sales team.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com