Tag Archives: mud recovery system

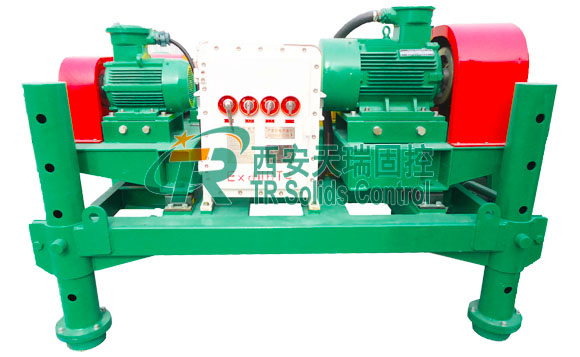

How is the TR Mud Recovery System

TR Solids Control is a professional manufacturer of solids control system and mud recovery system in China. TR mud recovery system is mainly applied in scenarios such as oil drilling, trenchless engineering, and infrastructure construction. Tr mud recovery system advantages of “integrated design + international certification + high cost performance”. It belongs to the domestic mid-to-high-end tier products. It has passed multiple domestic and international certifications such as API, ISO9001, and ISO14001. It exports cover many countries in the Middle East, Southeast Asia, etc. It has both domestic adaptability and international compliance.

Key parameters and advantages of TR Mud Recovery System

- Large processing capacity: 80m³/h-350m³/h

- High separation accuracy: Solid-phase control accuracy: ≥5μm

- Core technologies: Solidsworks 3D modeling, modular design. The four-stage purification technology (vibrating screen + sand/mud remover + centrifuge) has a higher separation efficiency. Special materials are resistant to abrasion, and the service life of vulnerable parts is over 30% longer.

- After-sales service: Response time: On-site service within 24-48 hours (domestic)

- Personalized customization: It can be specially customized according to the special requirements of customers. Each product is 3D modeled by Solidsworks, allowing customers to have a clearer understanding of the solution.

- Comprehensive certification qualifications: TR Solids Control has passed the American API certification and quality management system certification. Some of the products have passed the CE and CU-TR certifications. And it has multiple products that have passed the CE audit. It has multiple product patents (shale shaker, Drilling Waste Managemnet System)

Disadvantages of TR Mud Recovery System

Although it may not be well-known, the TR mud recovery system works well and is more cost-effective.

Solids Control System is Key Equipment

The Solids Control System is key equipment combination used in drilling engineering for purifying and treating drilling fluid. The function of the solids control system is to remove cuttings carried from the formation in the drilling fluid. maintain the stable performance of the drilling fluid. Drilling fluid not only serves to cool the drill bit and lubricate the drilling tools. It also can prevent wellbore collapse and carry cuttings back to the surface.

If solid impurities accumulate for a long time, it will lead to an increase in the viscosity of the drilling fluid. This not only increases the energy consumption of drilling but may also cause safety accidents such as stuck pipe. The solids control system is known as the “blood purification system”

The working process of the solids control system :

- The sand-containing drilling fluid returned from the bottom of the well first enters the mud shale shaker to remove large rock cuttings.

- The initially purified drilling fluid flows into the desander to separate medium-sized sand particles. The recovered drilling fluid enters the intermediate tank.

- The drilling fluid in the middle tank is conveyed to the desilter by a sand pump. It remove fine mud particles.

- The drilling fluid enters the centrifuge to separate ultrafine particles and meet the reuse standards.

- The purified drilling fluid is uniformly mixed by the agitator, supplemented with necessary chemical treatment agents. re-pumped into the bottom of the well by the drilling pump to complete the circulation.

- The vacuum degasser removes natural gas, air and other gases from the drilling fluid in real time. preventing the density of the drilling fluid from decreasing due to gas invasion and ensuring drilling safety. The drilling fluid tank serves the functions of storage, buffering and sedimentation buffering. It ensuring the continuous and stable operation of all equipment.

If you need mud recovery system and solid control equipment, TR Solids Control is your best choice.