Tag Archives: Drilling fluid shale shaker

Solid Control Spare Parts for Foreign Client

For our solid control equipment such as shale shaker, mud cleaner, desander, desilter, some spare parts are needed to be replaced at fixed period. At present, we could supply many spare parts for Derrick FLC500, FLC2000 series, Mi Swaco Mongoose shale shaker and mud cleaner. At last week, we finished the production and package of shale shaker and mud desander spare parts in our workshop. They have delivered to foreign client by air.

12″ desander cyclones and other spares will be shipped soon.

Regarding this order, it mainly includes 3pcs 12” desander cyclones, gauge, manifold inlet, manifold outlet for Swaco 2-12 D-Sander. Also includes hex head screws, hex nuts, lock washes, cable glands for Mongoose shale shaker. They are shipped together for one customer in Africa. In addition to these spare parts, we also provide shaker screens, float mount assy, channel protector, side support assy, cross support assy, lifting device, 10” desander cylone, 4” desilter cyclone for both Derrick and Mongoose shaker and mud cleaner.

Shale shaker spare parts are popular by customers.

TR Solids Control is a professional manufacturer of mud solids control equipment and drilling waste treatment systems integrating product development, production and sales in China for over 11 years. Our solid control equipment and relevant spare parts have been exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia, African, Australia, Europe etc. All of customers are satisfied with the quality and performance. Please contact us freely for any question or interest.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com

Three Daily Operations of Linear Shale Shaker

There are two main types of shale shakers according to different vibration motion, linear motion shale shaker and balanced elliptical motion shale shaker. Generally linear motion shakers have super sieving effect. However, with the passage of time and improper operation and use, the machine will become more and more sluggish. Even some parts will be damaged. So the maintenance is very important. The following are the three daily nursing operations of linear shale shaker for your reference.

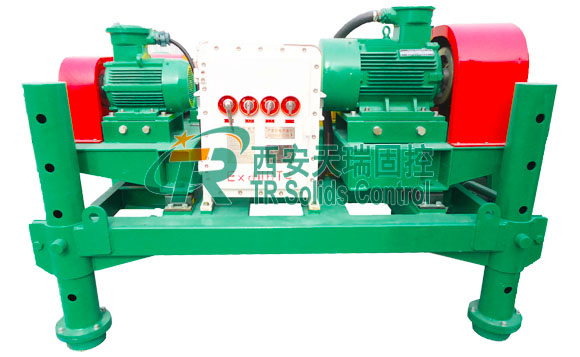

TRZS584 shale shaker is widely used in oil and gas.

Three daily operations of linear shale shaker:

- Oil injection. Lubrication parts such as bearings of linear shale shakerare generally filled with oil guns. The nozzle injection can be replaced according to different equipment, and some also canuse connecting tools.

- Protection. Damaged parts such as bearings have certain protective measures to prevent the bearing from affecting production due to excessive wear, avoid other debris from damaging the bearing, and prevent the bearing from heating up due to rotationprocess.

- In addition to checking the tightness of boltsregularly, you can also use pressure bolts to ensure that the bolts are tight.

TR linear motion shale shaker has high performance.

TR Solids Control is a well-known manufacturer and exporter of shale shaker with rich experience in China. Our shale shaker includes high G drying shaker, BEM shale shaker and linear shale shaker. Our factory and company are Quality Management System ISO 9001-2000 certified. We operate international oil and gas drilling mud separation system with excellent sales, service, manufacturing, distribution service. If you have any inquiry of shale shaker, welcome to contact us at any time!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com