Tag Archives: China Solids Control System

The Components of Solids Control System

Describe the Components of the solids control system

The solids control system is composed of multi-stage purification equipment, auxiliary equipment and pipeline systems. All levels of solids control equipment work in collaboration to achieve purification from coarse to fine.

The Components of Solids Control System

- Mud Shale Shaker:

Primary Solids Control equipment is also the “first line of defense” of the solids control system. The large particle cuttings (with a particle size of ≥74μm) in the drilling fluid are separated by high-frequency vibration.

The processing volume is usually 1.2 to 1.5 times the circulation volume of the drilling fluid, ensuring the efficient operation of subsequent equipment.

mus shale shakers can be classified into linear shale shakers and elliptical shale shakers. elliptical shale shakers are widely used in deep Wells and horizontal well drilling. it features high screening efficiency and strong processing capacity. - Desander:

Secondary Solids Control equipment. The desander adopts the principle of hydrocyclone to separate sand particles with a diameter of 20-74μm from the drilling fluid. It is usually used in conjunction with shale shakers. The sand grains separated by the cyclone fall into the small vibrating screen below to further recover the drilling fluid. - Desilter:

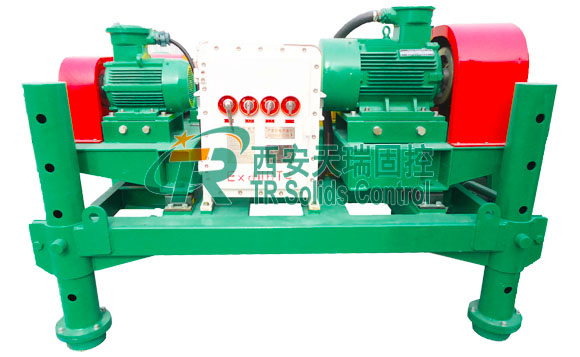

The third level in the solids control system. The sludge separator separates fine sludge particles of 10-20μm. The shaker screens of the deslimer is generally configured with 120 mesh. The sand removal cyclone has a smaller diameter and higher separation accuracy. It can effectively reduce the mud content of drilling fluid and maintain the stability of rheological properties. - Decanter Centrifuge:

Four-level deep Solids Control equipment. Solid-liquid separation is achieved by utilizing centrifugal force. Centrifuges are mainly used to separate ultrafine particles of 5-10μm. It is suitable for precision drilling scenarios with extremely high requirements for drilling fluid performance. It is mainly used for shale gas development and deep-sea drilling. It can enhance the reuse rate of drilling fluid.The centrifuge is components of solids control system.

Other equipment in the Components of Solids Control System:

The Components of Solids Control SystemIncluding drilling fluid tank, agitator, sand pump and vacuum degasser. Together, they form complete solids control system.

Solids Control System is Key Equipment

The Solids Control System is key equipment combination used in drilling engineering for purifying and treating drilling fluid. The function of the solids control system is to remove cuttings carried from the formation in the drilling fluid. maintain the stable performance of the drilling fluid. Drilling fluid not only serves to cool the drill bit and lubricate the drilling tools. It also can prevent wellbore collapse and carry cuttings back to the surface.

If solid impurities accumulate for a long time, it will lead to an increase in the viscosity of the drilling fluid. This not only increases the energy consumption of drilling but may also cause safety accidents such as stuck pipe. The solids control system is known as the “blood purification system”

The working process of the solids control system :

- The sand-containing drilling fluid returned from the bottom of the well first enters the mud shale shaker to remove large rock cuttings.

- The initially purified drilling fluid flows into the desander to separate medium-sized sand particles. The recovered drilling fluid enters the intermediate tank.

- The drilling fluid in the middle tank is conveyed to the desilter by a sand pump. It remove fine mud particles.

- The drilling fluid enters the centrifuge to separate ultrafine particles and meet the reuse standards.

- The purified drilling fluid is uniformly mixed by the agitator, supplemented with necessary chemical treatment agents. re-pumped into the bottom of the well by the drilling pump to complete the circulation.

- The vacuum degasser removes natural gas, air and other gases from the drilling fluid in real time. preventing the density of the drilling fluid from decreasing due to gas invasion and ensuring drilling safety. The drilling fluid tank serves the functions of storage, buffering and sedimentation buffering. It ensuring the continuous and stable operation of all equipment.

If you need mud recovery system and solid control equipment, TR Solids Control is your best choice.