What Features Does TRQJ Series Mud Cleaner have?

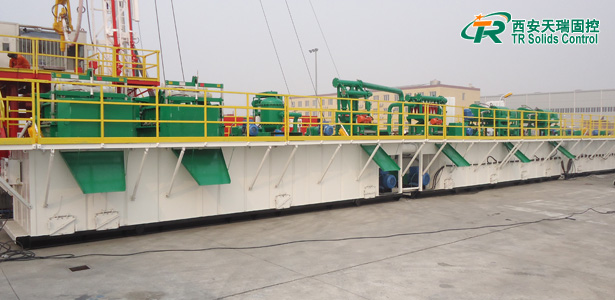

Mud Cleaner is the second class and the third class solids control equipment which is the newest type to treat the drilling fluid. TRQJ series drilling cleaner are combined from Desander, Desilter and also Underflow Screen. Our cleaner has the higher cleaning function compared with separated desander and desilter. In addition to the reasonable design process, it equals another shale shaker. Its structure is compact, also it occupy small space and the function is powerful. We can design customized cost-effective mud cleaner for customers special needs. It can meet almost all needs for oil & gas well drilling fluids treatment system also HDD Mud Recycling System.

Drilling fluids cleaner, China mud cleaner manufacturer

What features does TRQJ series mud cleaner have?

- Compact design with small footprint, also with top feed and weir feed two option.

- Mechanical Deck is adjustable during operation, so reliable performance.

- Polyurethane ( PU ) material or high-chromium cast iron for desander also desilter cones.

- Desilter cones can install between eight and twenty 4″ or 5″ desilter cones, each cone can process 80 GPM, and makes a separation between 15 and 45 μm.

- Desander cones can install between one and three 10″ desander cones, each cone can process 500 GPM, also makes a separation between 45 and 75 μm.

- Hook-strip shaker screens for fast screens changing with screens.

Good price mud cleaner, high quality cleaner, API standard mud cleaner

TR Solids Control could supply one-stop solution of mud cleaner. Furthermore, TRQJ cleaner is widely used in trenchless HDD, tunneling construction, city bored piling, oil & gas drilling, Drilling Waste Management, Oil Mud Seperation, environment protection, Coal Bed Gas Solids Control System, also mining, etc. Waiting for your inquiry!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com

Vertical Cutting Dryer For Russian Project

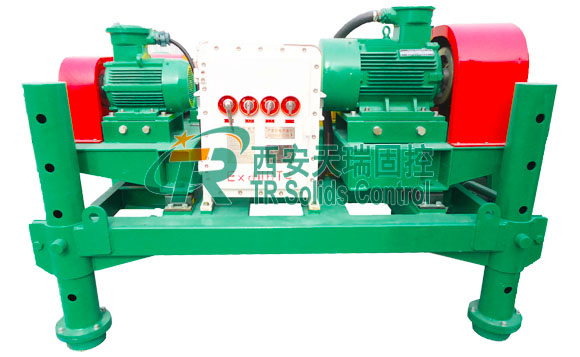

Last week, TR completed the manufacturing of 1 set TRCD930C vertical cutting dryer. It has shipped to our Russian client on September 12th. This equipment is the starting point for our long-term cooperation based on mutual trust. It will be used for post-treatment of oil sludge, so requires strictly in design also manufacturing. Furthermore, From the preparation of raw materials, the selection of vibrating motor, also welding standards including the accessories, there is a complete set of technical requirements. Finally we live up to expectations and deliver the dryer on schedule.

Vertical cutting dryer for drilling waste management, good price vertical cutting dryer

Regarding this set of vertical cutting dryer, the model is TRCD930C. Also handling capacity is 30-50T/h. Maximum diameter of basket is 930mm. Also the basket gap is 0.25-0.5mm. Rotating speed arrives 900r /min. Air knife inlet pressure is 0.69mpa, while air knife air supply is 1.8m3/min. Fuel tank capacity is 60L. Main motor power is 55kw. Oil pump power is 0.55kw. Dimension is 2750*2130 *1800mm. Also a set of technical document offered along with our dryer. In addition, we will provide free phone or video guidance to client after the dryer arrives.

High efficiency vertical cutting dryer, good quality vertical cutting dryer

Above all, TR Solids Control is a professional manufacturer of vertical cutting dryer. It is widely used in drilling waste management and oil & gas drilling currently. Furthermore, if you have any inquiry about mud agitator, shear pump, centrifugal pump, jet mud mixer, vacuum degasser, shale shaker, mud cleaner, decanter centrifuge, shaker screens etc, welcome to contact with us. TR team will do our best to support your business!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com