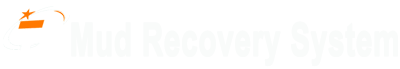

Centrifuge & Dryer in Operation at Drilling Site

After one-month operation, TR decanter centrifuge and vertical cutting dryer get positive feedback from our customer. They both have good and stable performance in oil and gas drilling field. We have rich experience on designing and manufacturing turnkey treating equipment which can be effectively used to treat different kinds of drilling waste includes OBM, WBM and SBM.

TR decanter centrifuge and vertical cutting dryer get positive feedback from our customer.

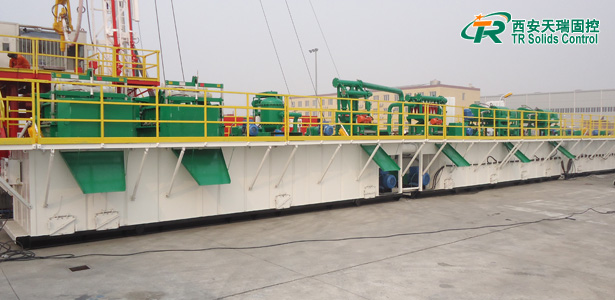

The model of decanter centrifuge is TRLW450N-2 with handling capacity of 50m3/h. Bowl diameter is 450mm, and bowl length is 1250mm. Rotary speed could arrive 3200rpm. This centrifuge is used to treat the particles ranging from 5μm-7μm. TR Decanter Centrifuge can meet with different requirements of mud treatment under various drilling conditions. In addition, model of our vertical cutting dryer is TRCD930C with handling capacity 30-50T/h. TR Vertical cutting dryer has been done strict balance testing for all major rotary components to minimize vibration & noisy. It is the ideal products for oil based drilling waste management.

Our dryer and centrifuge support oil drilling.

If you are looking for ideal equipment for your drilling waste management? TR Solids Control is your good choice. We have different schemes for both WBM and OBM. TR is a professional supplier of solid control equipment, mud recycling system and various petroleum equipment. Our products have been exported to Russia, America, Middle East, South America, Southeast Asia, Central Asia, African, Australia, Europe etc. Our company is willing to cooperate and make common progress with friends at home and abroad with first-class products, first-class service and reasonable prices.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web:www.trsolidscontrol.com

www.drillingmud-system.com

Composite Shaker Screens Shipped to Middle East

Shaker screens are common vulnerable part of shale shaker and mud cleaner. Composite type screens are perferred among clients for higher abrasion resistance and longer service time. At last week, we shipped 200pcs Mongoose composite shaker screens to a big drilling company in Middle East. They all passed strict inspection and with high quality carton box and wooden case package as per requirement before delivery.

Composite shaker screens to a big drilling company.

The size of our Mongoose shaker screens is 585*1165mm. The mesh our client ordered ranges from API 100 to API 230. Screen material is made of stainless steel 316, and frame material is top standard plastic injection. Screens will be packaged for 1 piece in one carton, and 30 pcs in one wooden case. They are manufactured according to both API and ISO standard. This kind of shaker screens also can be used in TR own shale shaker such as TRZS584 linear motion shaker and TRPS584 balanced elliptical motion shaker.

Our shaker screens are all passed strict inspection and with high quality.

In addition to composite shaker screen, we also supply flat type and pyramid type shaker screens. TR shaker screens could be equivalent with many international brand like Derrick, Mi-Swaco, Nov Brandt, Kemtron, Brandt King Cobra. Our screens are widely used in trenchless HDD, Drilling Waste Management, city bored piling, oil & gas drilling, tunneling construction, Coal Bed Gas Solids Control System, micro-tunneling, environment protection, mining, Water Drilling etc. Contact with us for more information!

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web:www.trsolidscontrol.com

www.drillingmud-system.com