OBM Drilling Waste Management Shipment

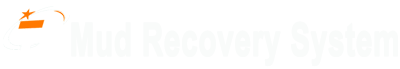

As the professional manufacturer in China, TR Solid Control could design and manufacture various model Drilling Waste Management or or Cutting Dryer System according to the customers requirement. On May.10th, one new batch of oil based drilling waste management was shipped to our old customer. Currently this system is widely used in Chinese domestic market for compact structure and high efficiency.

Oil based drilling waste management was shipped to our old customer.

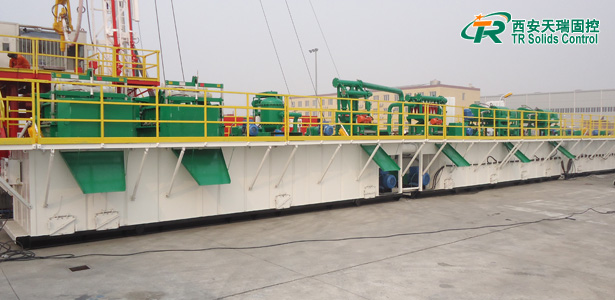

This system is composed of TRCD930C vertical cutting dryer, TRLW355N-1 high speed centrifuge, mud tank, centrifuge supply pump and other auxiliary accessories. Processing capacity of our dryer could reach up to 30-50 T/h with basket diameter 930mm. Rotary speed is 900r/min. Bowl diameter of our TRLW355N-1 centrifuge is 350mm, and bowl length is 1250mm. Processing capacity is 40m3/h. TR drilling waste management system can effectively control the moisture content (6%-15%) and oil content (2%-8%) in drilling cuttings and stabilizes the liquid phase performance.

Our drilling waste management is with compact structure and high efficiency.

TR Solids Control is one of the most famous international brand for Mud Solids Control System & Drilling Waste Management in China. We have one stop service for Solids Control Solution of your oil gas drilling, CBM drilling, HDD, and water well drilling as well as the construction drilling mud treatment etc. For more information about our drilling waste management, please visit: www.trsolidscontrol.com/drilling-management-system.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com

Pyramid Shaker Screens Shipped to Europe

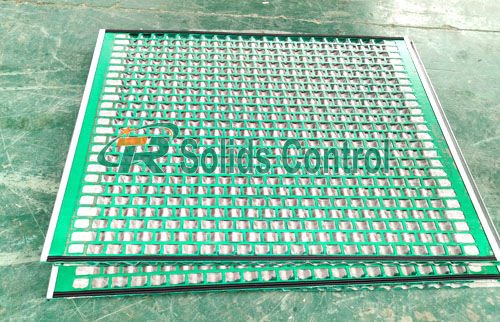

Shaker screens are common vulnerable parts of all kinds shale shaker and mud cleaner in drilling industry. After 10 days’ preparation and production, we completed 10pcs customized pyramid shaker screens for new European customer. They will be used as samples for testing before batch orders for their NOV Brandt shale shaker.

Pyramid shaker screens are completed for new European customer.

Dimension of these pyramid shaker screens is 915×1200 mm. Our client chose API 60, API 80 and API 100 for larger sieving particles application. Since shipment by train is much faster and cheaper, they preferred this method to the station. Compared with hook strip flat and soft screen, pyramid shaker screen has more available screening non-blank areas. Test shows that the capacity of the shaker gets about a three-fold improvement due to the screen’s corrugations. While this screen still maintains the equivalent cut-point level of flat shaker screen. This application reduces the number of shakers. Thus less space and less cost are realized. Three-dimensional shaker screen is absolute a superior replacement screen for many kinds of shale shakers.

New shaker screens will be used in oil and gas industry.

TR Solids Control could supply one-stop service for all your shaker screen requirements. We have been the leading China OEM supplier with quality, high performance shaker screens for over 10 years. Currently our shaker screens are available for FLC Series, Brandt VSM, Cobra Series, Swaco Mongoose and KEM-TRON shale shakers. We accept customized shale shaker screen as per client’s needs. Please send screen models, size, color, or drawings for an inquiry.

Contact Us: Maggie Xian|Sales Manager

Sales office: No.10 West of North 2nd Ring Road Xi’an City.

Factory Add.: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Mob.:+86-13186019625

E-mail: maggie@trsolidscontrol.com

Web: www.trsolidscontrol.com

www.drillingmud-system.com