Tag Archives: Oil sludge treatment system

Oil-Based Drilling Waste Management

In order to implement and follow environment requirements, TR Solids Control developed a set of drilling waste management independently. This system makes the mud pit disappear completely, and can realize harmless treatment during drilling. TR team has made our own contribution to environmental protection.

Oil-based drilling waste management, liquids solids separation, DWM manufacturer

Our oil-based drilling waste management is mainly divided into waste drying collection unit, liquid phase separation unit. As for disposal of waste mud, we need to add gel breaker processing unit.

1.Thermal Washing Facility

In this process, thermal washing facility will be injected into a certain percentage of hot water. Then we transport oil-base mud drilling cuttings to the thermal washing facility with screw conveyor. The oil from the drilling cuttings off in the stirring of mixer continuously. At this time, the thermal washing facility completes this process.

2. Waste Drying Collection Unit

In this process, we transport the drilling cuttings treated by solids control equipment to high-frequency vertical cutting dryer with screw conveyor. After dryer treating, large particles of drilling cuttings in solids control equipment are separated and stripped.

(Solid-phase water content can be controlled within 10%) Drilling waste cuttings are collected and transported timely to the lower tank for caching and pre-treatment.

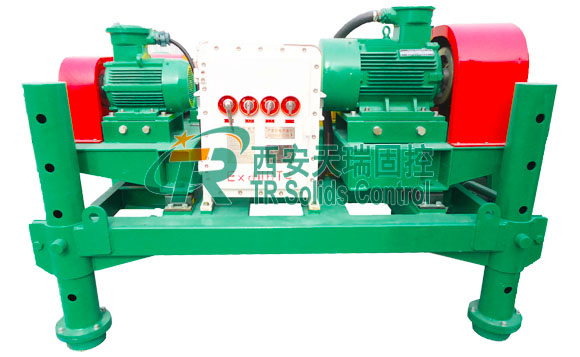

3. Liquid Phase Separation Unit

In this process, we transport the mud filtered by vertical cutting dryer to variable-frequency high speed centrifuge through industrial pump(screw pump) of the centrifuge for deep separation. After treatment, solid phase separated is collected, and liquid phase will be transported to drilling fluids circulating system for recovery through sand pump.

Mud circulating system, oil sludge treatment system, solids control unit

As a main and well-known manufacturer of solids control equipment and drilling waste management, TR Solids Control always put customers’ requirement in the first place. If you have any inquiry about shale shaker, shaker screen, mud cleaner, desilter, desander, mud agitator, jet mud mixer, decanter centrifuge, centrifugal pump, shear pump etc, welcome to contact us freely. TR will provide our best price and service to you.

Contact Us: Maggie Xian|Sales Manager

Sales office:No.10 West of North 2nd Ring Road Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Manufacture: No.60 Caotang Industry Zone Huxian County Xi’an City.

Tel:+86-29-86332919

Tel:+86-29-86332919

Call:+86-13186019625

Call:+86-13186019625

E-mail: maggie@trsolidscontrol.com

E-mail: maggie@trsolidscontrol.com